As electric vehicles are getting popular, Electric Vehicles Battery Management System Development to manage the batteries can be a great business idea.

And every morning waking up to honking and bad air quality is the new schedule. Yeah, we all hate it, we all discuss it in the comforts of our drawing rooms but how many of us are doing anything about it?

Well, truth be told there are a lot of small steps that we can take to make sure that we give the future generation cleaner air. Car Pooling, public transport, and the most recent electric vehicles are some of the best alternatives.

Talking about electric vehicles, the latest buzz in the town is Ola e-scooters apps. With delayed deliveries and marketing issues, somehow these vehicles are on road now.

This doesn’t solve our problem. Some users now complain about battery use. Well, surely that is an issue here.

The Solution: A strong and reliable battery management system for electric vehicles.

Let’s dig in a little deeper and understand how the whole electric vehicle bms works.

What Is a Battery Management System for EVs?

In recent days, the automotive industry is taking Electric Vehicles very seriously! There have been times in the past when these vehicles weren’t welcomed, and now they have marked their importance.

The public, governments, OEMs, tier-1 suppliers, and everyone else are vying to make electric vehicles a viable alternative to internal combustion engines.

Most of us, when feeling lost in the glitz and glam of EVs, forget the most critical component of an EV, the battery pack. It is basically 40% of the vehicle’s overall cost.

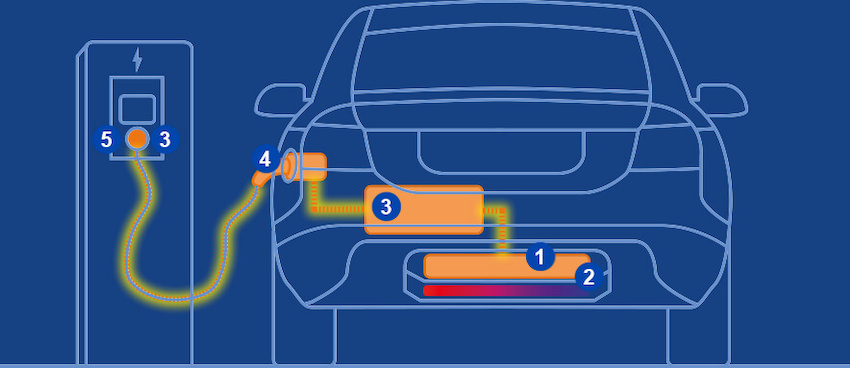

The Lithium-ion cells that power the EV engines are housed in the battery pack, which also includes a smart solution known as the EV Battery Management System or electric vehicle BMS.

Any high-end battery-operated electronic gadget that you have ever used has a BMS. Your smartphone’s battery percentage or overall battery health display is the show put forward by the integrated battery management system.

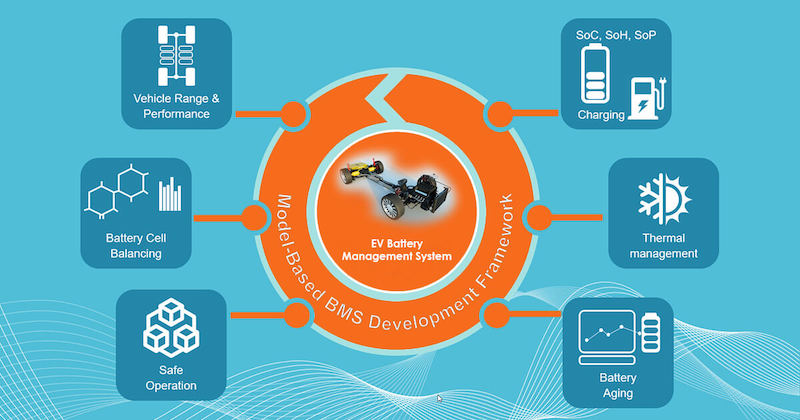

Basically, the software development works using a complex algorithm and is designed to monitor each cell of the battery and calculate percentages, health, and other information. The complexity increases significantly as we apply the battery management component to an electric car.

Before we discuss the details of the battery management system for electric vehicles, let’s examine our progress over the years and where it all started.

Read Also: How to Develop EV Charging Station Locator App: Cost & Features

Electric Vehicles a Brief History

The story isn’t as new as it seems. It’s just evolving over and the recent trends have only added to the innovation.

1832: Yes the story dates back almost 2 centuries back. It was in 1832 that the first crude electric vehicle came into existence. Although it was only after the 1870s that electric cars gained some popularity.

1889-91: Des Moines-based William Morrison came up with the first electric vehicle in the US, although it looked more like a carriage than a car, the story just began.

The late 1890s: Real electric vehicles gained popularity in the market only in the late 1890s and early 1900s. Back then compared to smelly pollutants emitting gas and steam-powered vehicles, electric cars were quieter and easier to drive.

1901: It was here that Edison realized that electric vehicles were the future and decided to work on better and stronger batteries.

1901: It was now that Ferdinand Porsche entered the market with the first hybrid car, Lohner-Porsche Mixte, that worked on gas as well as electricity stored in batteries.

1900-1912: With the turn of the century, electric vehicles gained popularity and became a major market presence.

1920: As the Texas crude oil was discovered, gas filling stations boomed and with better roads, gasoline-driven vehicles gained popularity.

1968-1973: The gas prices around the world soared real high making the shift towards EVs again.

Recommended Read: MVP App Development Company

1973: It was here that the modern-day EV journey began. Many big and small automobile companies became a part of the shift. General Motors came up with the urban EV car model.

1974-1977: Sebring Vanguard Citicar entered the market with one of the most successful electric cars of the time.

1996: EV1 gains a cult status as the modern EV in the market.

1997: Prius by Toyota becomes the first mass-produced car that gained popularity increasing the status of EVs too.

2006: Tesla Motors announces it would enter the market with the first luxury EV car with a range of over 200+ miles.

2010: First publicly available plug-in hybrid was available for sale.

2010: Nissan enters the market with Zero tailpipe emission car LEAF. With so much going on in the market, the battery prices dropped too.

It is only recently that the EV batteries have evolved to their current phase and become a little affordable. The journey is over 200 years and in that time the world saw the rise, fall, and urgency of Electric Vehicles.

To make sure that the electric vehicles that run on the road are safe and fine, their battery needs to be maintained and checked often.

This necessity has given birth to the modern-day Battery Management System that is interesting and engaging.

Bonus – Why Car Wash Businesses Must Invest In Car Wash App Development

Electric Vehicle Battery Management System Needs and Benefits

Car battery management systems have significantly grown over the years and have made their needs felt by all vehicles and electronic devices.

EV Battery Management System’s Key Responsibilities

We all know how dangerous a lithium-ion battery pack can be. It is similar to a little explosion-packed. To avoid any mishappening one needs to take care of factors like voltage, charge, and temperature. An unregulated thermal runaway can result in an explosion or fire, both of which can be fatal to the owners of the electric vehicle.

To avoid the risk each EV battery is integrated with a BMS that helps one take precautions and avoid these situations.

The functions that a typical Electric Vehicle BMS performs are listed below.

Cell Monitoring

It is essentially important to make sure that the battery is monitored when charging or draining. Any inconvenient scenario, as well as the triggering of the safety system, must be found out and reported. This function is performed by integrated circuits that are equipped with cell monitoring algorithms.

The cell monitoring circuit records the cell voltage and temperature and sends the information to a cell management controller via a chain of command.

Some algorithms are conducted at this point to calculate the state of charge (SOC) and state of health (SOH).

State Of Charge

This is used to affirm that the battery is never overcharged or undercharged. Since SOC displays how much energy is left in the battery, it can be treated as a fuel indicator too. Additional algorithms can be run using this data to determine how far the EV can travel before the battery has to be recharged.

Read Also: How to Start your Own Roadside Assistance Business – Develop Towing App like Uber

State Of Health

The SOH measures the battery’s overall health and provides information about its operating circumstances. Battery lifespan and maintenance schedules can be predicted using this data.

Another key aspect of cell monitoring is diagnostics. The battery management system for EV uses UDS-based diagnostics software to identify and submit fault codes and diagnostic information. These data points can resolve the problem or activate a safety mechanism based on ISO 26262 (Road vehicle safety certification).

Power Optimization

The optimization of battery power is a direct result of cell monitoring. The EV battery management system’s job is to keep the SOC and SOH parameters within the prescribed levels, while the cell monitoring functionality decides them. The EV battery management system decides how much current can be permitted in the individual cells when the battery is charging.

When the EV is operational, it starts discharging. The car battery management system integrated with the vehicle communicates with the vehicle’s motor controller, checks for the solution, and ensures that the voltage level doesn’t slump.

Safety of Electric Vehicle

Another primary concern that we need to consider is the undetected thermal runaway. This is one problem that can lead to a fractal mishap. As we have already discussed that BMS looks after the data such as voltage, temperature, and current to optimize the power a similar set of data is also utilized for ensuring safety.

If your BMS for car battery or any other vehicle battery is developed adhering to international standards, then surely it is a feel-safe system. Insulation of the vehicle body/chassis to avoid electric shock is another vital point to check for the safety of the vehicle owners.

Battery Charging Optimization

We all know that cells of the battery deteriorate over time. With a technologically advanced BMS, it would detect the rate of deterioration based on changes in battery parameters such as voltage, current, etc.

Let’s consider a situation here. If the battery cell is a little damaged by the heat and charges at a lower voltage than the rest of the cells, in this case, smart battery management system for electric vehicle would identify the issue and optimize the charging process so that all cells are charged at the same voltage. Thus here one would reduce the stress on the overall battery pack and only add to its shelf life. For sure the electric vehicle BMS diagnostics would save the issue as a trouble code that can be later worked on. But for the moment it would take an initiative where the driver is out of risk.

Another problem with the batteries is the oxidation in the terminals. This too leads to a reduction in the voltage where the car battery management system can easily adapt to the changes to extract the best performance from the battery.

Well-Defined Communication Channels

No matter how advanced and smart the battery management system for an EV is, it will fail if communication is hampered. To avoid any mishaps, it is important that the BMS developed is highly intuitive and reactive.

Related Post: Automotive Mobile App Development

Towards the End

Surely the road for EVs has been a rollercoaster. It was the dips that each time pushed the biggies in the picture to bring something bigger and better. As you move forward AN, SPI, and BUS cable are the latest in the field. If you are looking forward to entering the domain with some innovative idea, simply message us or connect with our experts.

With the latest technologies and trends, we can help you grow and build a strong presence in the market.